Zip-tie method

JEC has made

a you tube video showing this zip-tie method in action.

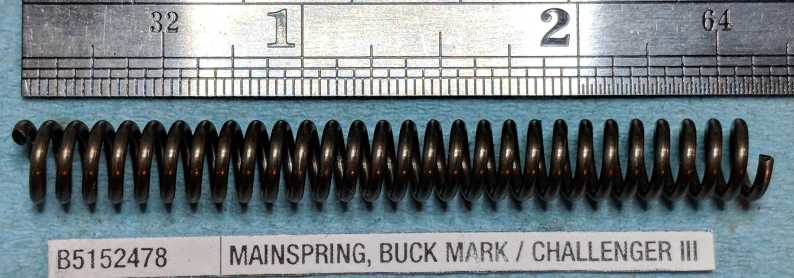

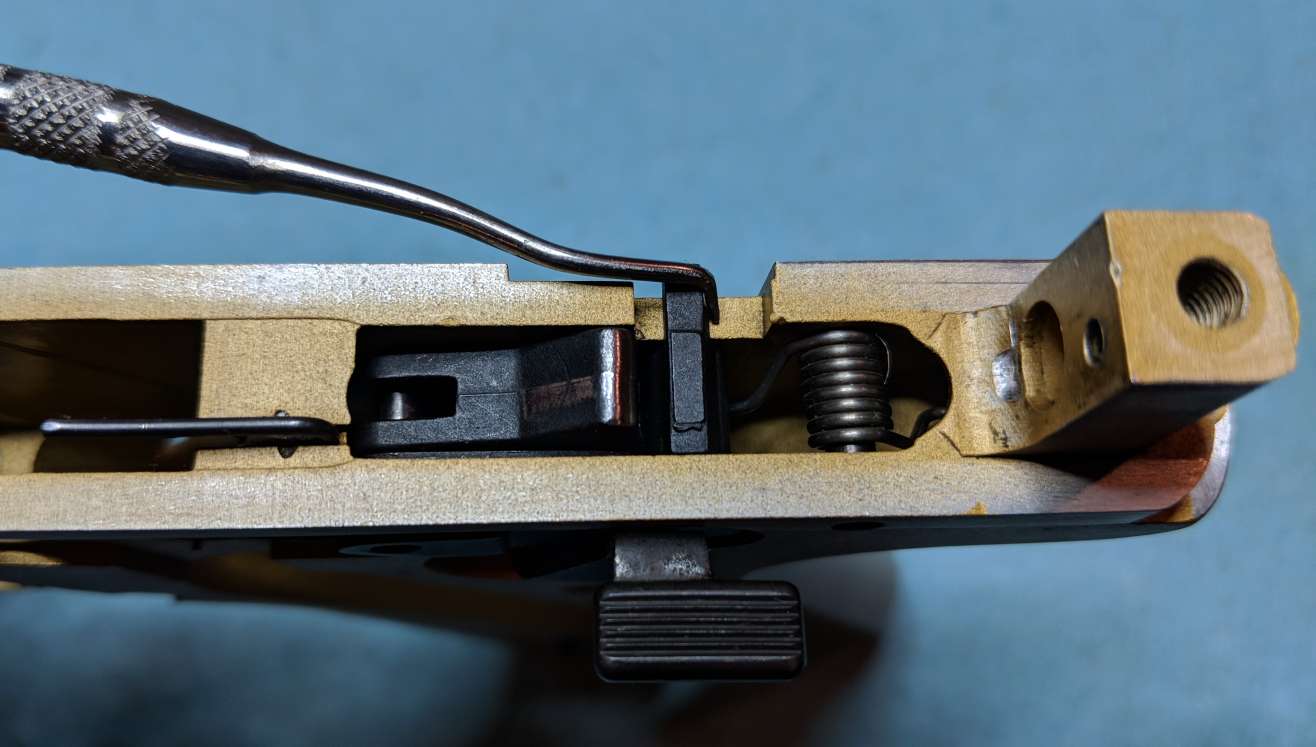

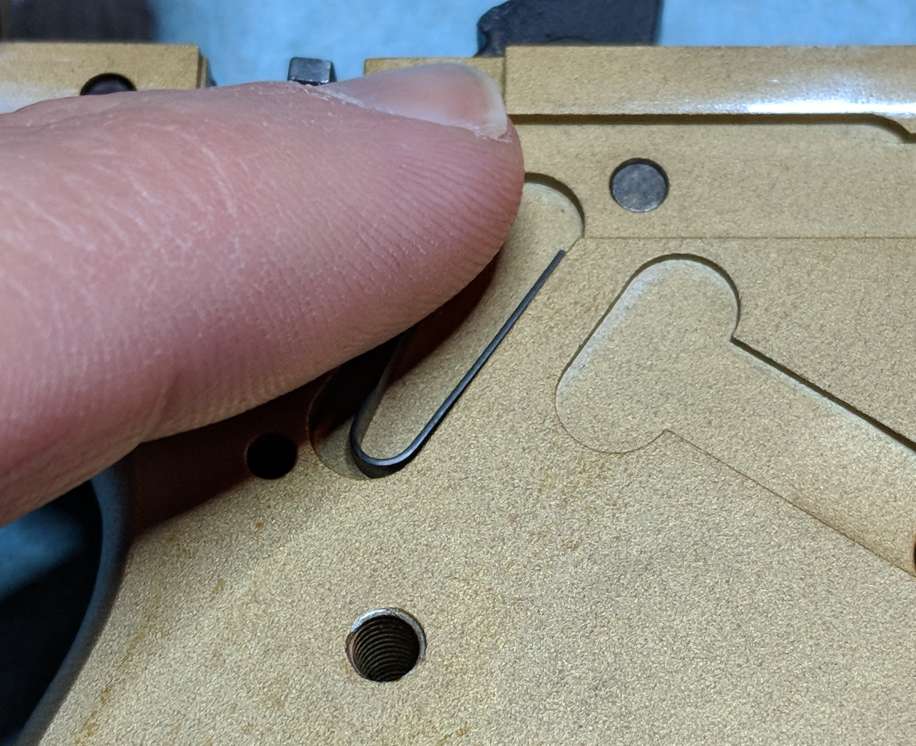

- Bend a zip tie into a U shape, and place it around the sear spring coils.

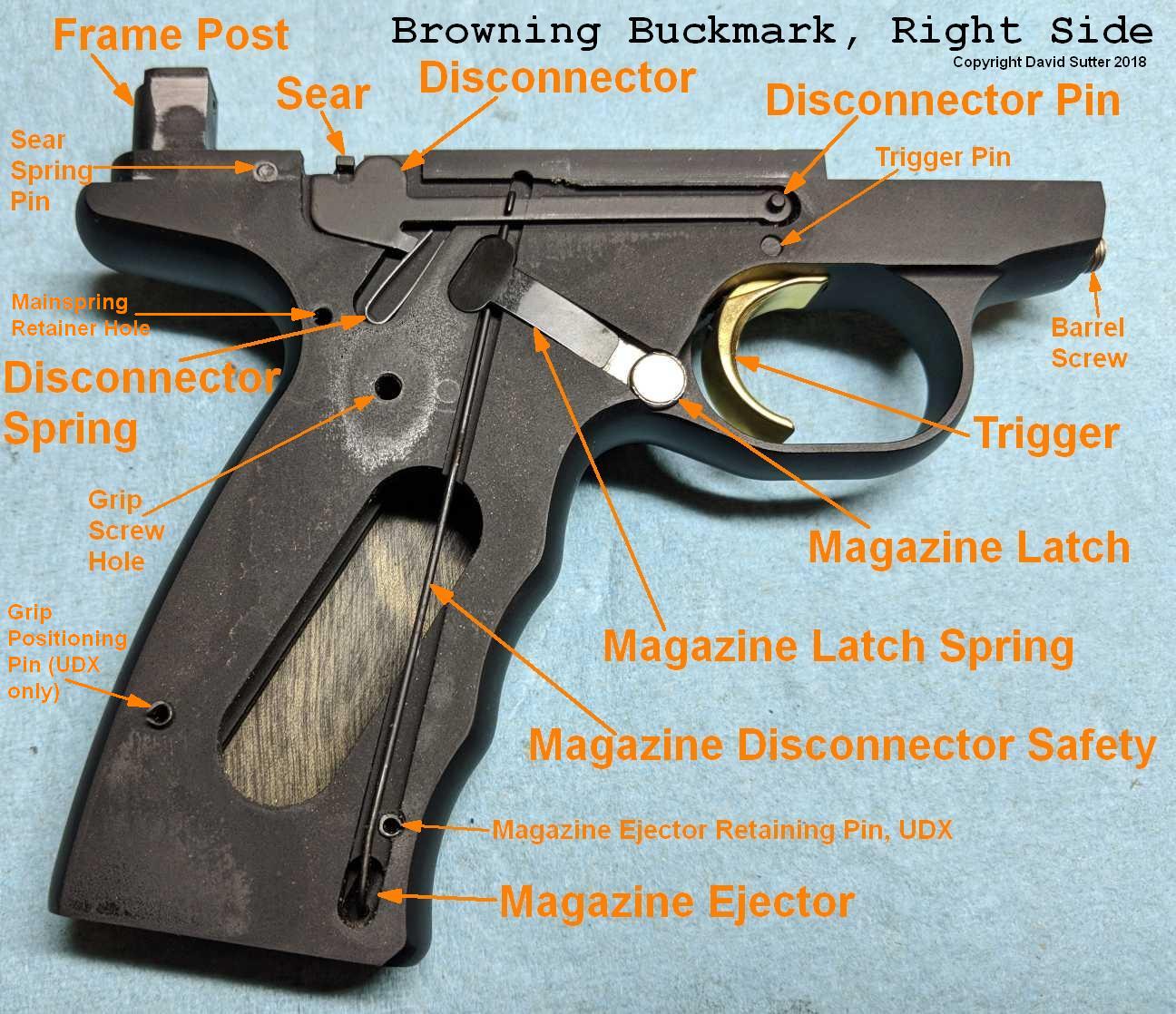

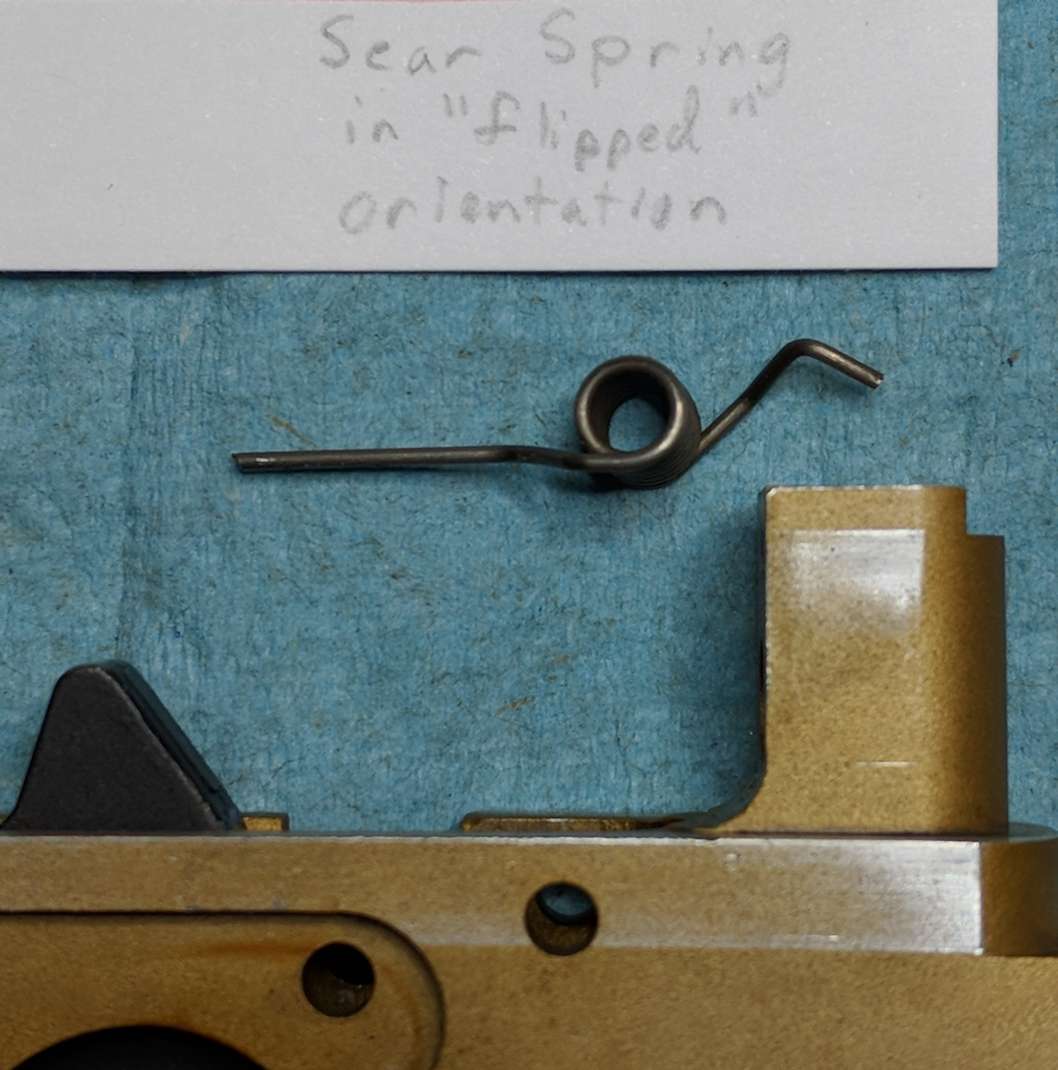

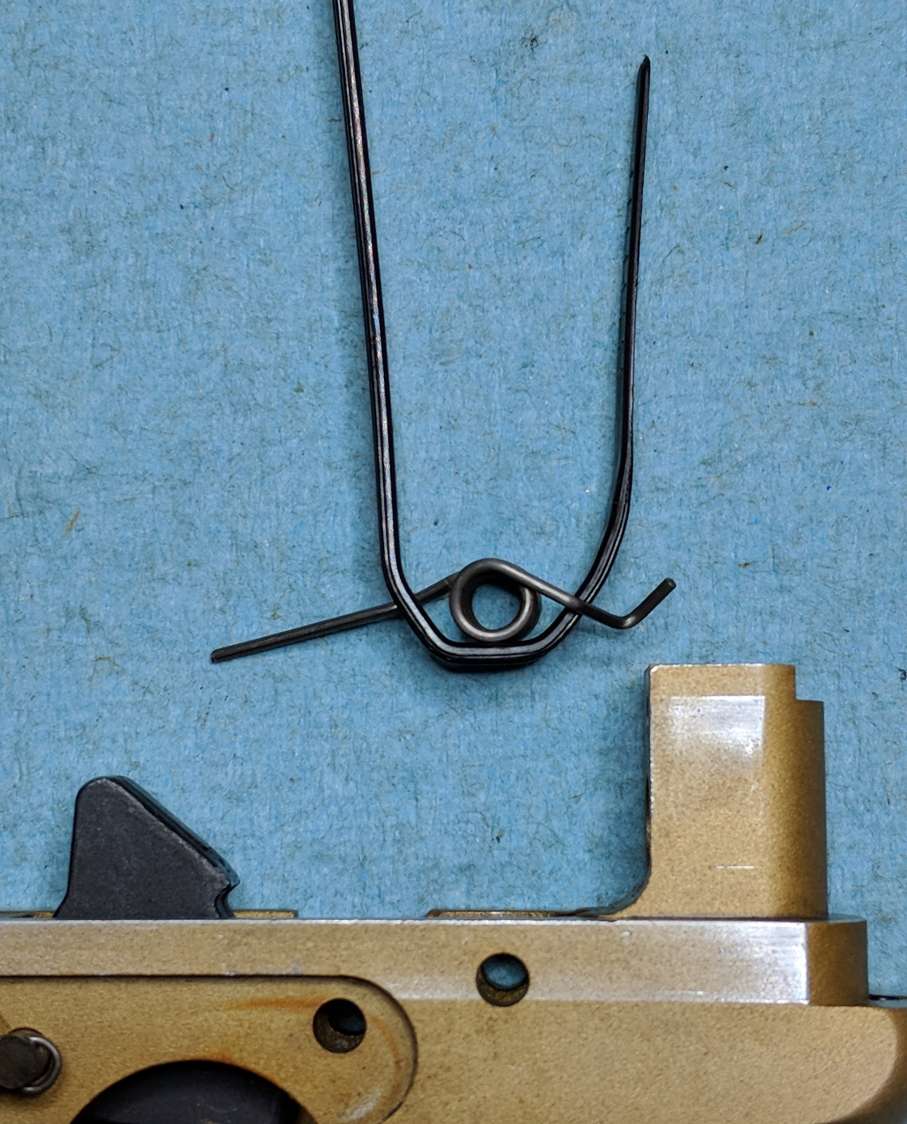

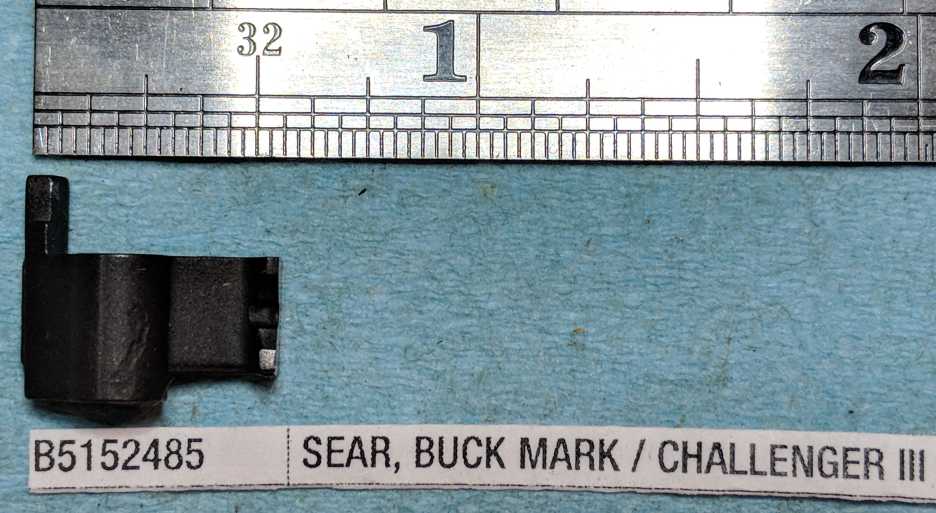

- Confirm sear spring orientation: long leg toward the front (always), and short leg toward the rear (always), legs at the top of the coils is the stock position, legs at the bottom of the coils is the "flipped" position.

- Holding the zip tie, lower the sear spring into the frame. Do not let go of the zip tie.

Holding the zip tie lower/closer to the spring gives you better control.

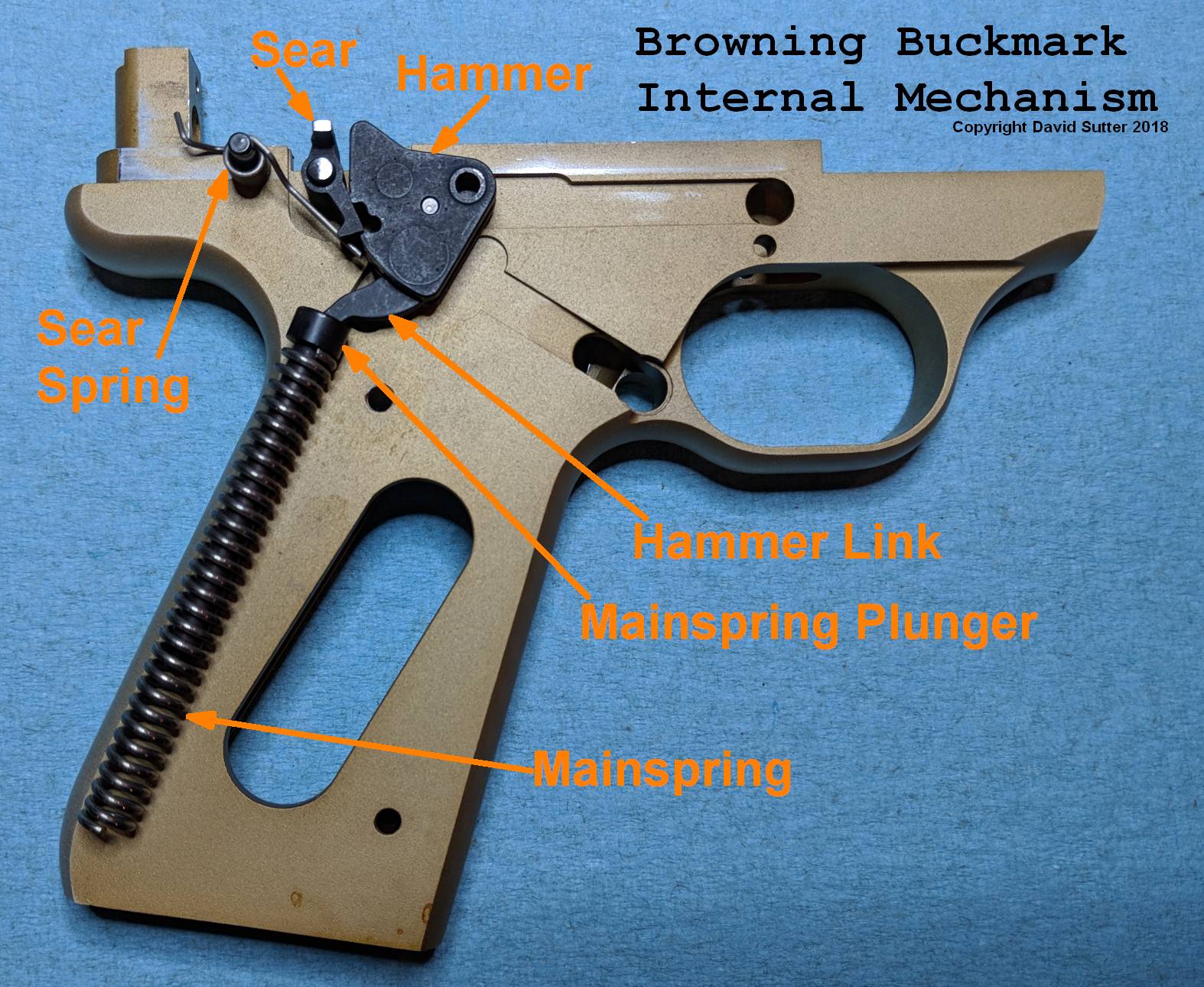

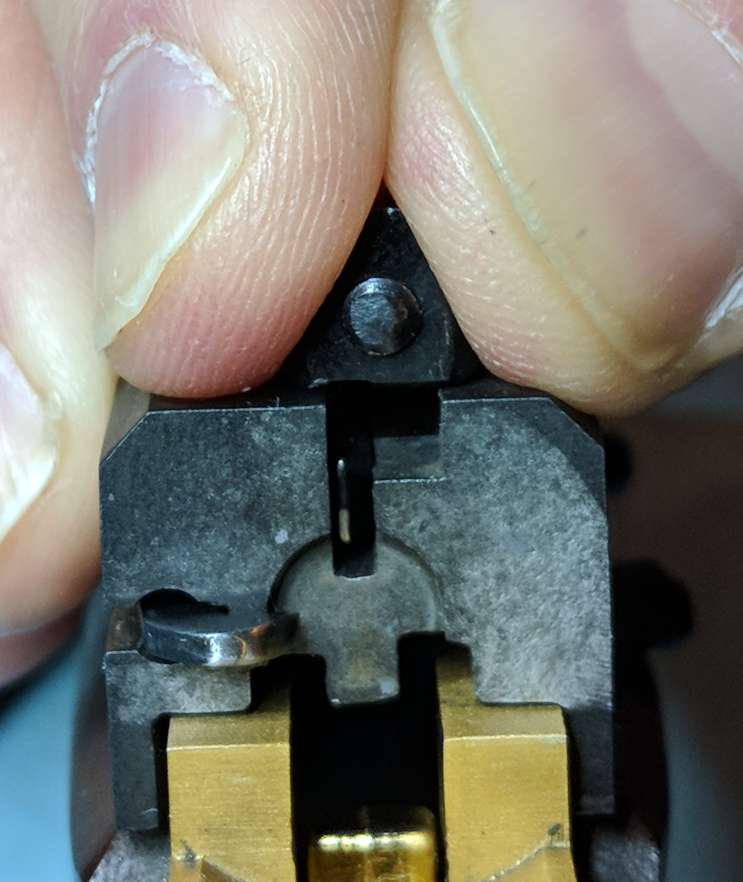

- Position the long front leg of the sear spring into the slot in the center of the hammer.

You may need to rotate the hammer forward/up to expose the slot.

If you are installing the sear spring while the sear is already in place, the front leg of the sear spring must go into the V-shaped notch at the bottom of the sear.

- Get the rear leg into place, using a small screwdriver or dental pick.

Cutting a small v-notch in the end of the screwdriver can make this easier (tip from bandnuts).

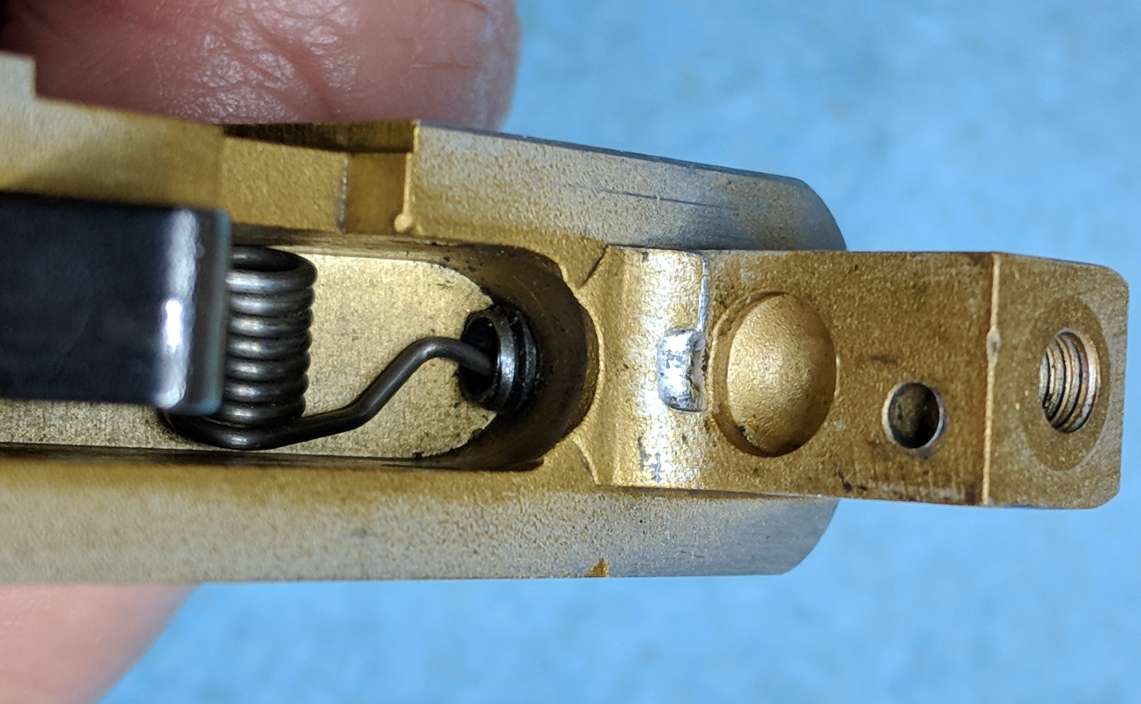

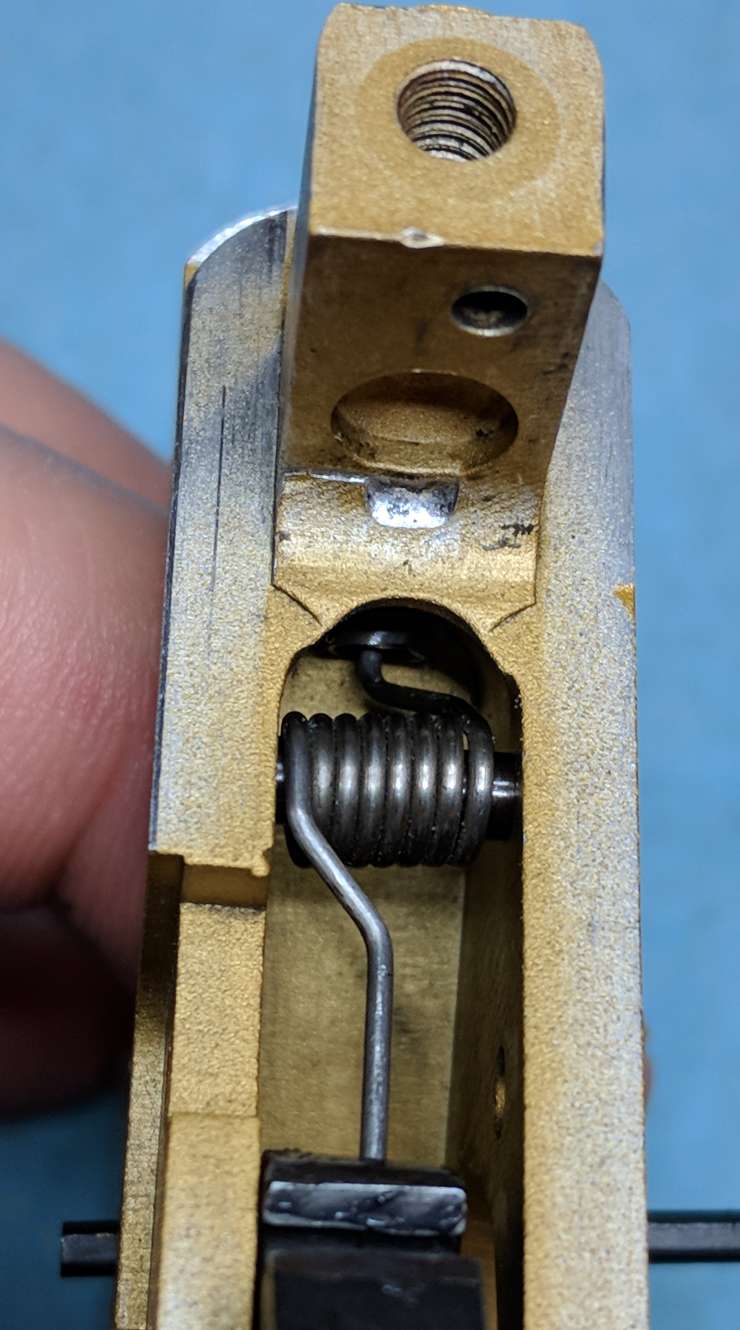

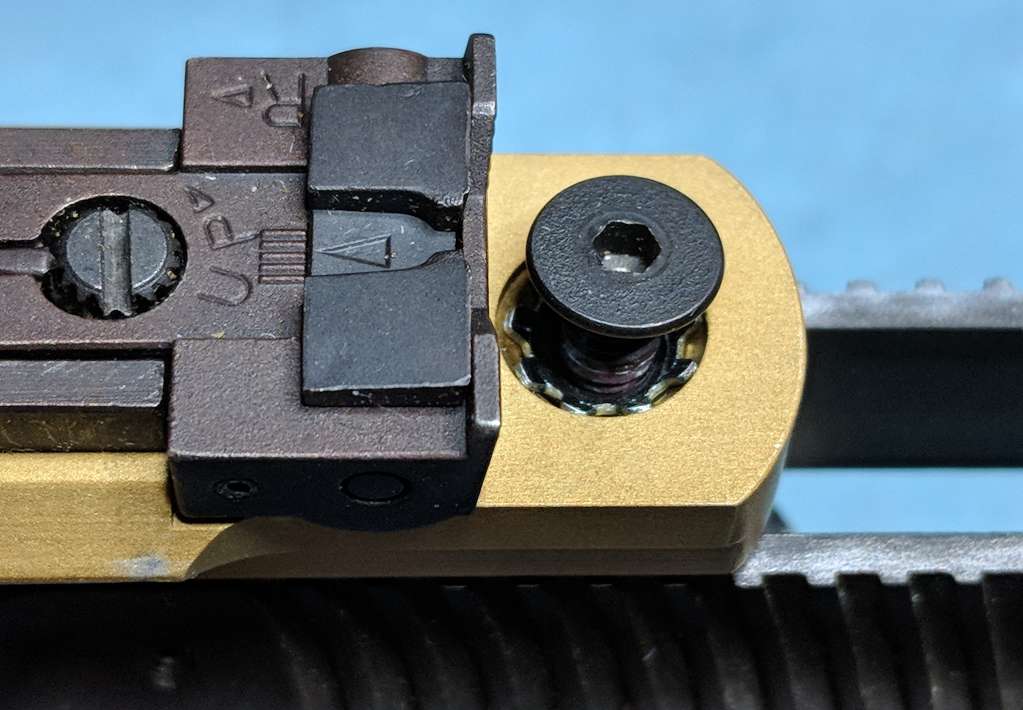

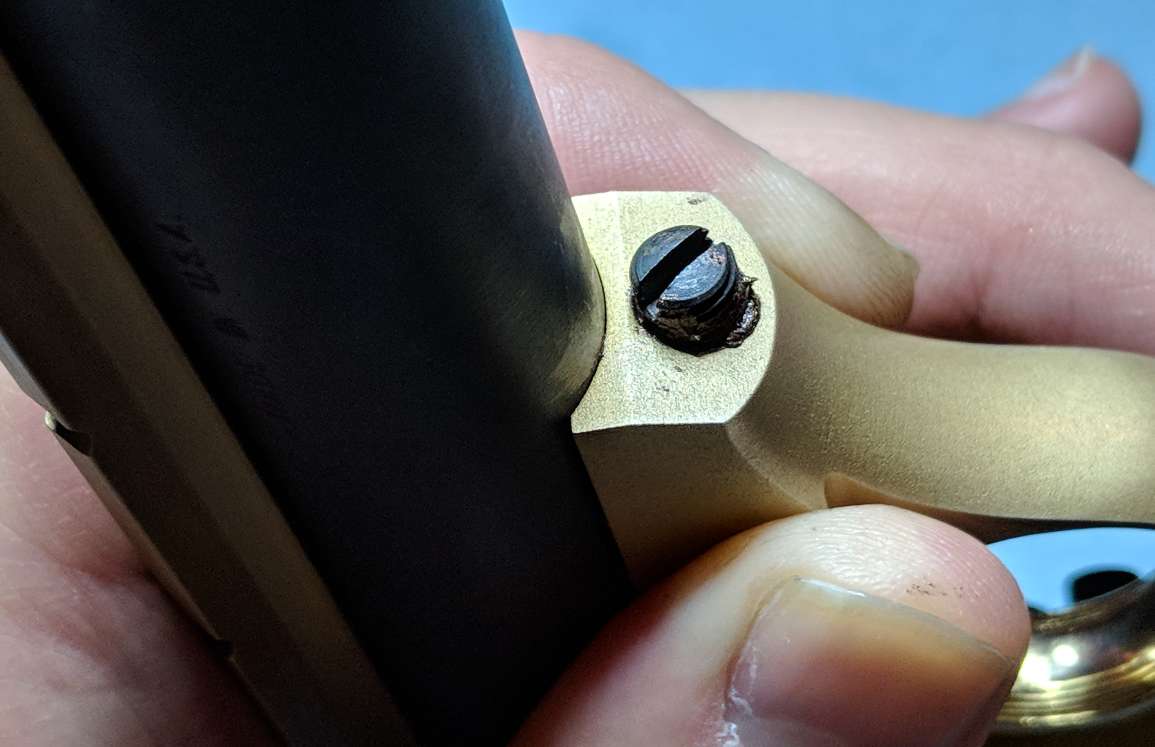

- For Buckmarks with the sear spring adjusting screw, the bent-up tip of the rear leg of the sear spring must go into the bottom of the adjusting screw. (See photo)

- For other Buckmarks, the rear leg must fit into the notch in the frame.

- Still holding both ends of the zip tie tightly, pull up on the zip tie, until the sear spring coils are lined up with the sear spring pin hole.

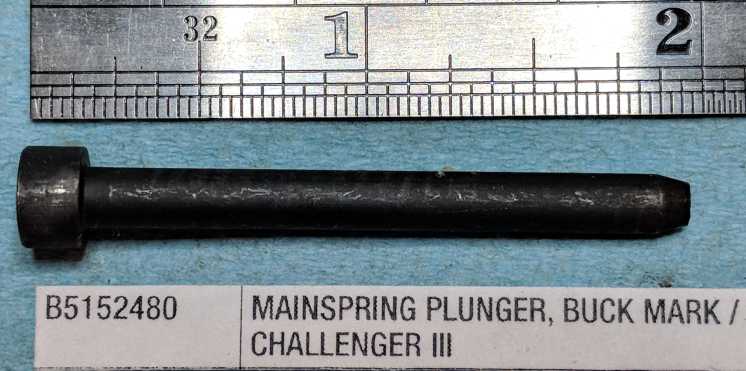

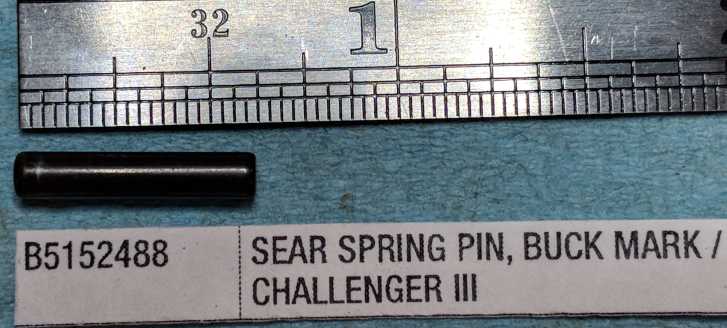

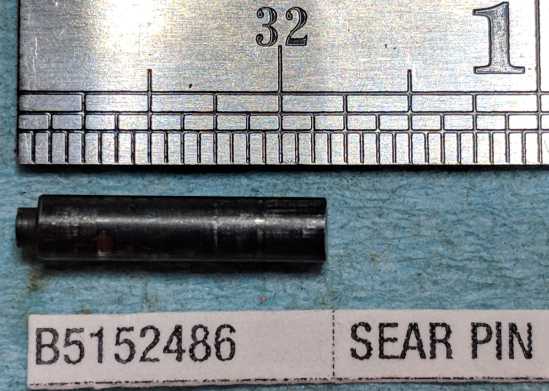

- Push the sear spring pin into the frame (either direction), and through the coils of the sear spring.

The pin should be flush with both sides of the frame.

One end of the pin may be beveled a little more than the other end. It's easier to insert the beveled end first,

but it probably doesn't make a functional difference.

- Pull the zip tie out, confirm that the legs are still in their correct positions, and you're done.

Alternate method #1: Hold coils above frame, position legs, lower coils into position

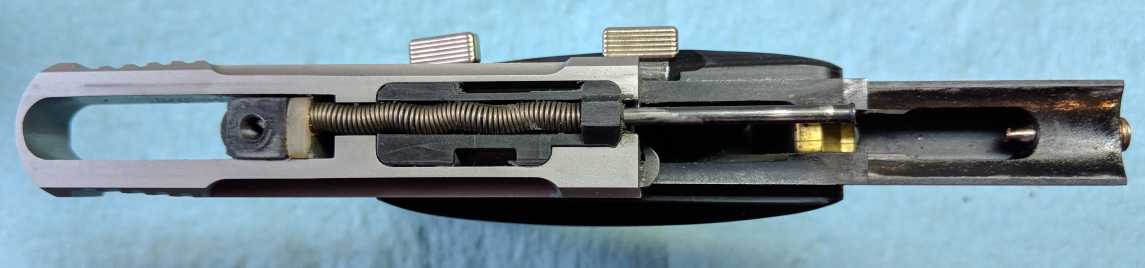

It helps to start by putting the frame in a padded vice. Put a small (1/16") allen wrench

through the coils and lay it on top of the frame, with the long leg forward, and the short

leg towards the rear, and the coils approximately over the sear spring pin hole. Pull the

short leg up, so that the long leg rotates down into the frame. Position the long leg in

the v-shaped notch at the bottom of the sear. Holding the allen wrench to keep the spring

in place, use small needle-nose pliers to grab the short rear leg and push it down into

its position (usually in a notch in the frame). With both legs in position, begin pulling

the allen wrench out of the coils, until one end is off the frame. Angle the allen wrench

down, lowering the coils, until you can begin pushing the sear spring pin through the frame

an into the coils. Push the pin in more as you slowly remove the allen wrench. Eventually

the spring will be completely captured by the pin, and the allen wrench will be all the way

out. Line up the pin with the frame hole on the far side, and push it the rest of the way

into place. This method described in slightly different words in

RFC Thread 922081 by user OCD

Alternate method #2: Insert sear spring into frame, then orient it and pull it up with a dental pick.

The basic idea is to drop the sear spring into the frame, and once it's down there, use a dental pick to get the legs into position,

and then use the pick to lift the spring up so that you can slide the sear spring pin into place.

Although the idea is straightforward, the problem with this method is that most people find it infuriatingly difficult to actually do this.

Chim, in

his instructions

(on

page 8) describes it this way:

"

Drop the sear spring into the frame and get it aligned with the pin holes. The pin has lots of clearance inside the coiled spring, so it isn't very difficult to line up"

Alternate method #3: Put a string through the coils first

Thread a piece of string through the coils (side-to-side), drop the sear into the frame,

use a dental pick to position the legs, then use the string to pull the spring up into position,

so that you can insert the sear spring pin. There is plenty of clearance inside the coils

for the string and the pin at the same time. This makes the step where you lift the spring

up into position MUCH easier than trying to do that with the dental pick, but I think the

zip-tie method is better because it also has that advantage, plus the zip-tie can be used

to help get the legs into position.

Alternate method #4: Partially insert the sear spring pin before positioning the legs

The basic idea is to get the sear spring captured before positioning the legs.

Insert the spring into the frame long/front leg first, then insert the pin halfway to

partially capture the sear spring. By only pushing the pin in part way, the sear spring

still has some wiggle room. Then use a dental pick to force the rear/short leg down into place.

Then drive the sear spring pin the rest of the way through. Perhaps this is possible on

some Buckmarks, but on the 1992 Gold Target, I could not see how to do this without

bending the rear leg of the sear spring pretty severely.

Alternate method #5: Install sear spring before the hammer

The basic idea is to install the sear spring first, then install the hammer/safety, then

install the sear. This way, you only need to worry about getting the rear leg of the sear

spring positioned correctly when installing the sear spring pin, and nothing else is in

your way. Then, when installing the hammer, you push the hammer down onto the front leg

of the sear spring. However, this method does make installing the hammer/safey more difficult,

since the sear spring is trying to push the hammer out of position while you are trying to

insert the hammer pin.

Why you should install the sear spring before the sear...

RFC POST from user BadaBing11 (from

RFC thread 1009433):

Install the spring before inserting the sear.

Then, install the sear, applying pressure to the spring with the sear. OMG, What a piece of cake that was.

All the videos I've seen on youtube say to install the sear before the sear spring.

I was at my wits end and darned near caved in to taking the gun to a gunsmith to get this done.

I tried this suggestion and it took less than three minutes.

I wouldn't remove the sear just to install the sear spring, but if you have both out,

definitely install the sear spring first, then the sear.

Notes on the Heggis Flip

The Heggis Flip is a common Buckmark modification intended to reduce trigger pull weight. It works because torsion springs (like the sear spring) offers more resistance when the legs are pushed in the direction that will tighten the coils, and offer less resistance when the legs are pushed in the direction that will loosen the coils. Torsion springs are intended to be used with the legs tightening the coils (they last longer this way, too). The stock orientation of the Buckmark sear spring is the normal/correct orientation of the spring. When flipped, the legs are being pushed in the direction that will loosen the coils, so it offers less resistance (reducing trigger pull weight).

The instructions for the Heggis Flip can be found at

RFC post 1468180

That post is post #52 (page 4 or so) of

RFC thread 174356

When doing the Heggis Flip, you do NOT flip the spring front-to-back, you flip the spring top-to-bottom.

In the stock configuration, the legs are at the top of the coils

In the flipped configuration, the legs are at the bottom of the coils

In either configuration, the long leg is always toward the front, and the short leg is always toward the back

If you flip it such that the short leg is in the front, you will have failures (probably trigger reset issues)